Our Products

Embossed Carrier Tapes

Cub Tech offers an extensive range of Carrier Tapes, manufactured using top quality & high specification base materials – PC, PS, PP, A-PET embossed carrier tapes & width ranging from 8mm – 88mm as standards in both conductive and non-conductive materials. PS material carrier tape sheet with thickness of 0.20mm – 0.50 mm can be catered to, as standards.

Our in-house design expertise, custom tooling and material manufacturing capabilities ensure well defined, strong pocket formation including deep pocket forming.

All carrier tape Engineering Design is performed in-house by our experienced team permitting quick responses to customer requirements raised during the design phase.

Cover Tapes (HSA / PSA Cover Tape)

Cub Tech offer a variety of cover tapes (also known as sealing tape) providing users a complete range of sealing capabilities and characteristics to achieve optimal sealing results (whatever may be the carrier tape material, used).

Our static dissipative cover tapes are available in both HS (heat seal) and PSA (pressure sensitive adhesive) (cold seal) and in a large assortment of widths [5.3mm to 81.5 mm].

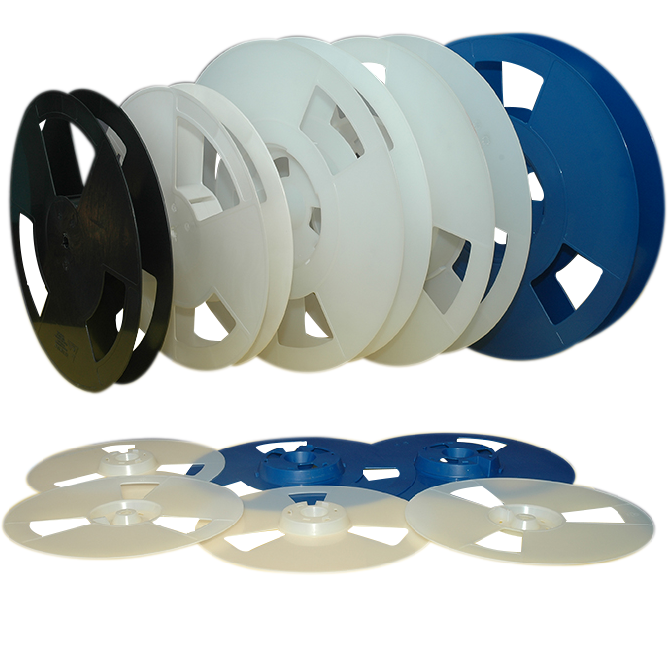

Plastic Reel

Cub Tech offers a wide range of plastic take up reels to provide maximum mechanical and ESD protection to components during transportation & storage.

Cub Tech can provide a broad range of reel options from stock, to support your tape & reel packaging requirements and minimize the need to hold stock.

Market available standard reels can be supplied.

* Reel Diameter: 7”, 13” & 15”

* Hub Diameter: 4”, 6” & 7”

* Reel Width: 8 mm – 72 mm

* Colors: Black, Blue & White

* Types: Anti – Static, Static Dissipative, Conductive, Natural

Vacuum Packaging Equipment

Cub Tech offers a flexible range of vacuum packaging machines that may be configured for a variety of industries, from semiconductors & electronics to food industry standards. To protect parts in storage or transport these machines vacuum package and heat seal to provide optimum atmospheric conditions for product preservation.

To provide ESD (Electro Static Discharge) protection, our range of vacuum packaging machines can be specified with an ESD option to ensure that ESD sensitive components & assemblies are vacuum packed within a static safe environment.

When used with appropriate barrier bags, vacuum packaging protects bag contents against physical damage, dust, ultra violet radiation (UV), radio frequency (RF) contamination, ESD, humidity, oxidation and corrosion.

All machines are compatible with antistatic aluminum foil type moisture barrier bags.

Vacuum Form Trays

Cub Tech can supply a wide range of vacuum form trays for packing and transpiration of electronic and semiconductor components. Vacuum formed trays can be custom made to any size, thickness and are constructed of various materials.

The following are the material types:

* HDPE

* ABS

* HIPS

* PET

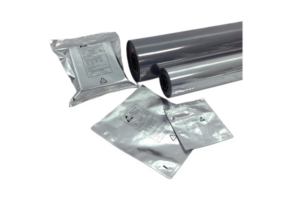

Moisture Barrier Bags

To maintain the dry condition of the Devices after baking the Devices are sealed under vacuum in a Moisture Barrier Bag (MBB). A Desiccant bag and Humidity Indicator Card (HIC) are placed in the MBB before sealing to maintain and indicate the condition of the product for the end user. The shelf life of product packaged in this manner is typically 1 year.

Moisture Barrier Bags provide packaged components with the ultimate protection from moisture and static damage. Cub Tech can supply MBB’s as per customer requirement.